-UPDATE YOUR BUILDING-

WITH A VARIABLE FLOW CONDENSER SYSTEM

-

SAVE SEVENTY PERCENT ON YOUR PUMPING COSTS

-

FP&L INCENTIVE

-

PUMPING EQUIPMENT LASTS LONGER

-

INSTALL WITH NO OUT OF POCKET EXPENSE

-

POSITIVE CASH FLOW

-

ASHRAE APPROVED

The VARIABLE FLOW CONDENSER SYSTEM (VFCS) was developed by Bass Automation Engineering over twenty-five years ago. The VFCS is installed in buildings that have water-cooled heat pumps for their heating and AC.

The VFCS is now required by the ASHRAE energy code for new construction. The system also qualifies for a substantial FP&L incentive payment.

-HOW THE SYSTEM WORKS-

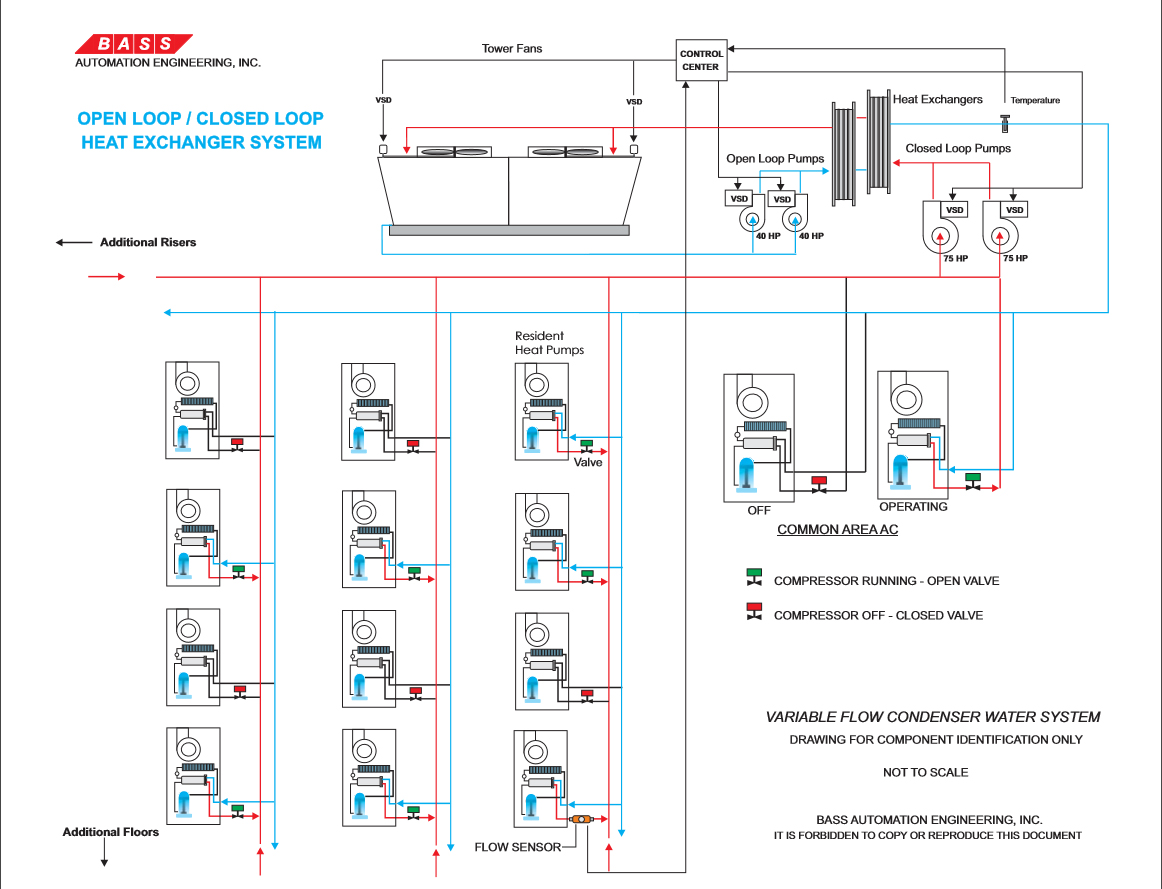

The diagram below shows a typical condenser pumping system in a high rise building. The example is a heat exchanger system with two, 40HP open loop pumps and two, 75HP closed loop pumps.

A building with pumps this size may have several hundred apartments. The diagram shows a sample percentage.

As shown in the diagram, the VFCS calls for automatic shut off valves to be placed on the AC units. The valves open (shown in green) if the compressor is running and close (shown in red) when the compressor shuts off.

Frequency drives are installed on the pump motors and allow the flow from the pumps to be controlled according to demand. Demand is indicated by the remote flow sensor, shown in the diagram.

Before the VFCS was developed, the condenser system required that all four pumps run at 100% speed, 24 hours a day. It may be possible to turn off one of the smaller, open loop pumps during the winter months, but this is a very small percentage of the overall operating cost. There are usually no automatic controls for this control strategy.

Without the VFCS, there is no way to reduce the flow and cost of running the larger, closed loop pumps. This is because each AC unit requires a specified gallons per minute (GPM) of water flow to operate properly and efficiently. If you turn off one pump, or somehow reduce the flow of the system, every AC unit in the building will be operating under reduced flow conditions. The AC units will run at higher compressor pressures causing higher amperage levels. They will cost more to run and their operating life will be reduced.

-HOW THE SYSTEM CUTS HORSEPOWER AND ELECTRICITY -

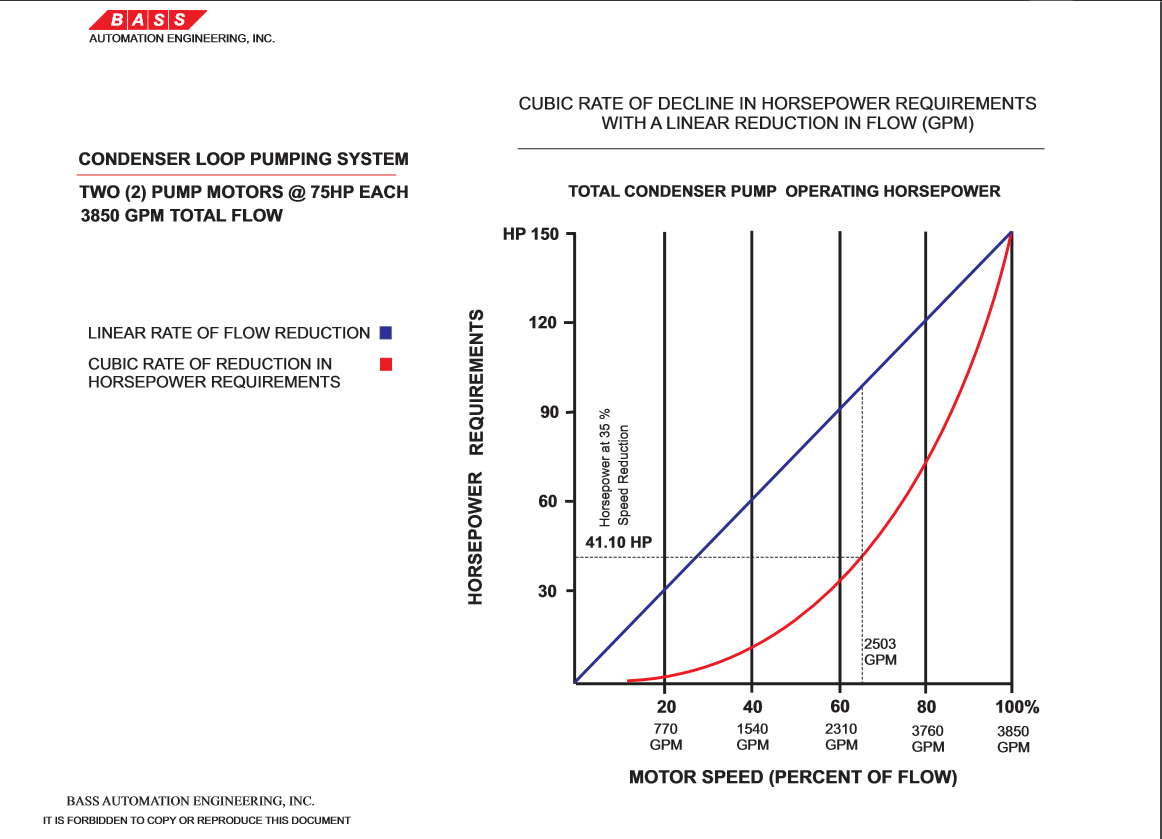

Although our sample system has four motors, we will first address the two 75HP, closed loop pumps.

The graph below shows how, as we reduce the flow of the system to match the building demand, the horsepower and resulting operating costs, are reduced at a cubic rate.

Assume our sample building has 300 apartments. The graph shows a point in time when:

--35%, or 105 apartments, aren't running and have a closed valve

--the demand on the building is 65%

--the system flow is reduced from 3850 GPM to 2503 GPM

--the HP is reduced from 150HP to 41HP

-COST AVOIDANCE-

The average 65% building AC load, illustrated in the graph, is the load level we use to predict the cost savings of a VFCS installed by us.

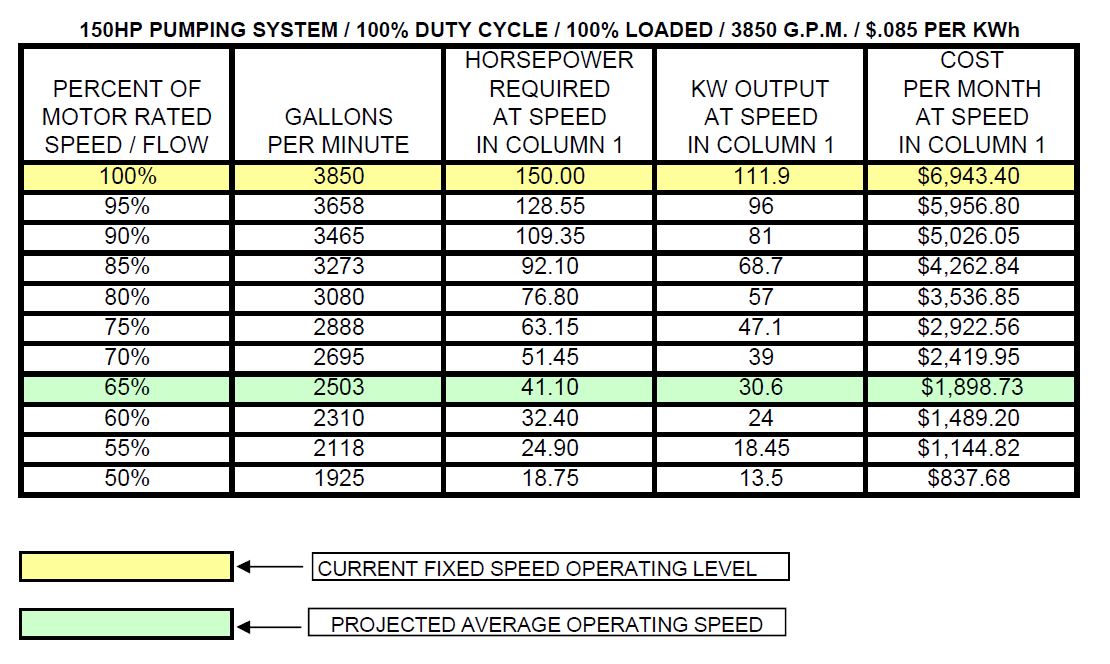

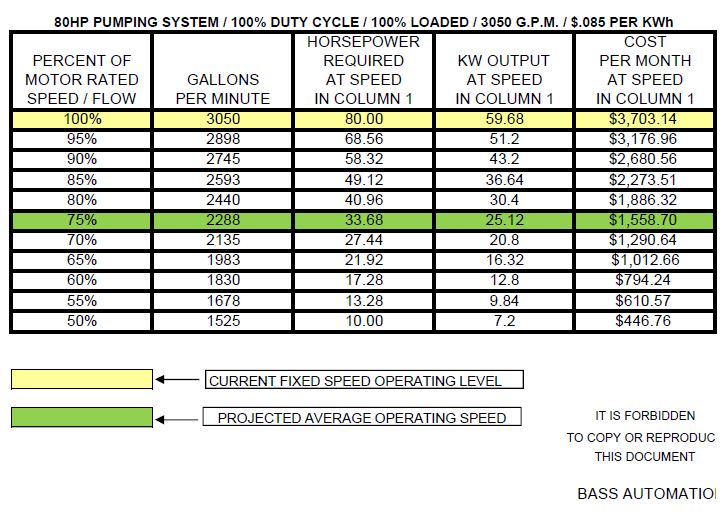

If you look at the table below, you will see how various speed/flow reductions translate into horsepower and $Dollar savings.

The cost to run these two pumps, before the VFCS was installed, was $6943 per month (this is an actual installation). We guaranteed this customer a 35% average load reduction, which would bring the operating cost to $1898 per month, a savings of $5045 per month. The performance of the system exceeded the guarantee.

-OPEN LOOP PUMPS-

Our example also has two, 40HP open loop pumps. This is an additional opportunity for significant cost avoidance. The flow from these pumps is also matched to the load on the building, based on condenser water supply temperature. We guaranteed an average 25% speed reduction to this customer for their open loop pumps. Again, our guarantee was exceeded.

Total cost avoidance for this building, open and closed loop, exceeds $7500.00 per month.

-SYSTEM APPLICATION-

The VFCS can be installed in any building that has a water cooled heat pump system. The system has the fastest payback where pumps are 20HP or larger.

The system can be installed on its own or as a component of an overall Building Automation System (BAS).

-COST / FINANCING-

The system cost is determined by the size and number of the pumps and the number of valves. Simple payback is very fast--usually twenty to forty-eight months.

In most cases, financing can be arranged whereby the customer has no out of pocket expenses and a guaranteed positive cash flow.

-ADDITIONAL BENEFITS-

--Audible noise levels are reduced.

--Lower amp draw reduces operating temperatures at motors and all wiring

connections and retards insulation breakdown.

--Lower RPM means less wear on bearings, seals and impeller blades.

--Soft start function eliminates stress on components from normal starts.